The confectionery industry is constantly updating, even in the candy molds category. suppose you are considering buying a new candy depositor or expanding your business range, you need to know this new type of candy mold, which will save you time and manpower in the next few years.

Chapter 1. What is a quick-release candy mold? (also called clip-type candy mold)

Chapter 2. What’s the difference between the two types of candy molds?

Chapter 3. What are the materials of the candy mold?

Chapter 4. Two categories for the quick-release candy mold configuration

Chapter 5. What are these lip-type Candy molds applications?

Chapter 6. What are the advantages of clip-type candy molds?

Chapter 7. Can I change my existing candy mold to this new type?

Chapter 8. How to avoid the mold ejection pin from breaking our company logo?

Chapter 9. What’s the MOQ for the quick-release candy mold?

Chapter 10. How to clean the molds?

Chapter 11. What are the certificates of your candy molds?

Chapter 12. Why iSweetech?

Chapter 1. What is a quick-release candy mold? (also called clip-type candy mold)

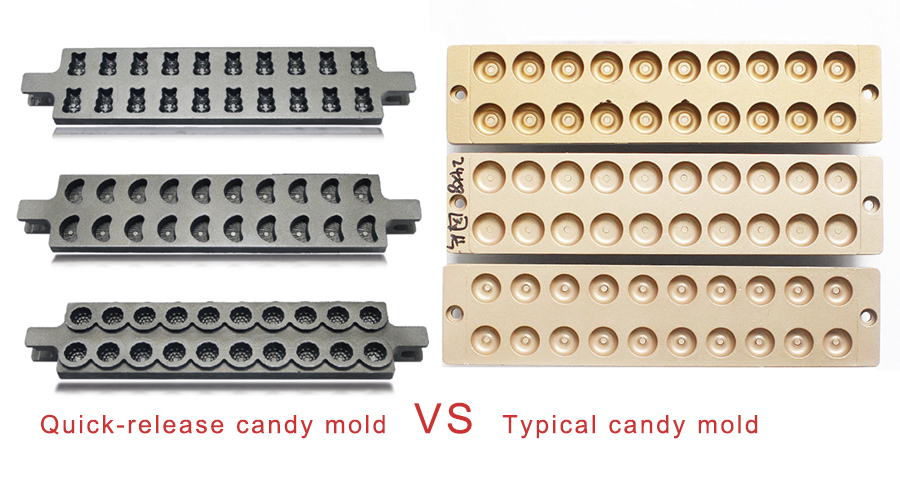

The quick-release candy mold is an upgrade from the typical mold. The mold frame has a unique design that uses a silicon tool connected to the moving chains. the candy cavities’ method is the same as the typical ones. let’s see the pictures below.

Chapter 2. What’s the difference between the two types of candy molds?

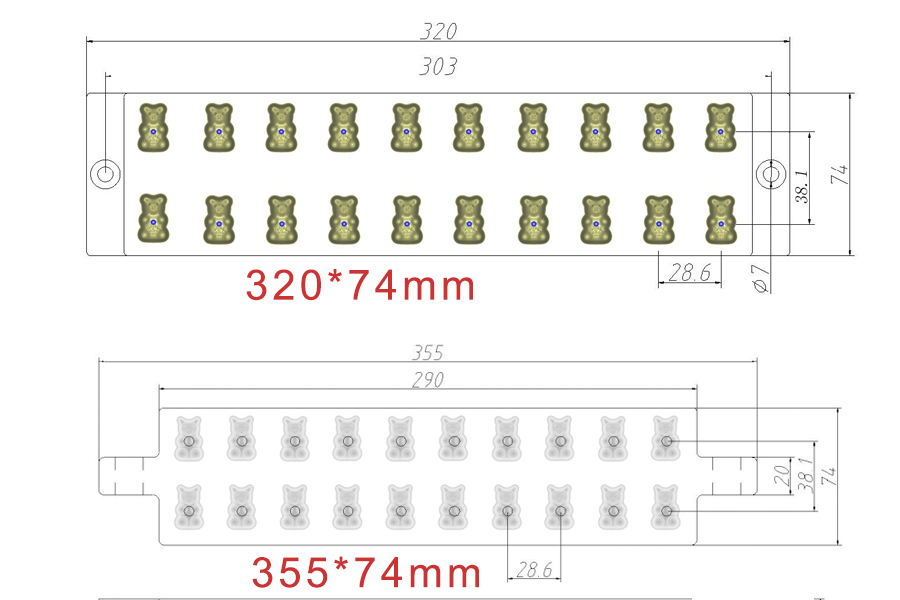

The candy molds are customized, and the cavities may be from 5 to 20, let’s based on a flat candy mold with 20cavities, a comparison of the below three views.

| Typical candy mold | Quick-release candy mold | |

| Frame size | 320*74mm | 355*74mm |

| Connection way with the mold chains | Screws, Clamps, rings. | Silicon tool |

| Time consumption for change over 100pcs molds | 2hours | 30mins |

Obviously, the quick-release mold is a better choice.

Chapter 3. What are the materials of the candy mold?

No matter the typical candy mold or the quick-release candy mold, they are all made from aluminum alloy and then coated with Teflon. The aluminum alloy will speed up the candy forming speed compared with silicon candy molds, the Teflon coating is food standard and avoids candy sticky on the mold surface. the candy mold also has ejection pins for pushing out the candies quickly.

Chapter 4. Two categories for the quick-release candy mold configuration

2D mold, which only has patterns on one side, the other side is flat.

Chapter 5. What are these lip-type Candy molds applications?

The molds can be used for making:

- Hard candies

- Toffee candies

- Fudge

- Gummy candies

- Lollipops

Chapter 6. What are the advantages of clip-type candy molds?

We can summarize the following advantages of clip-type molds.

- Easy installation

- Easy change over the molds to other shapes

- Easy cleaning

- Save manpower and time.

- Good appearance in the line

Chapter 7. Can I change my existing candy mold to this new type?

If you are using the typical type of candy mold right now. you can not change to the quick-release type mold. Why? first, the mold chain sizes are different. second, the mold overall size is different too. this will affect the movements of the molds on PLC.

Chapter 8. How to avoid the mold ejection pin from breaking our company logo?

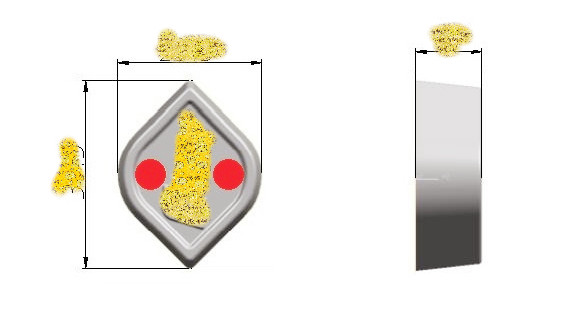

The flat candy mold with an ejection pin in the middle. which will push the candy out of the mold quickly. if you want to design a mold with your logo, then the ejection pin may break your logo. so our solution is to design two pins on each cavity to avoid your logo in a whole part. example design like bellow pic.

Chapter 9. What’s the MOQ for the quick-release candy mold?

In general, the mold MOQ(Minimum Order Quantity) for each design is 100pcs.

if you mold quantities over or less than this, we can discuss it.

Chapter 10. How to clean the molds?

The candy molds need to be cleaned regularly. You can use hot water or cleanser essence to clean them all and blow dry or put them in the sun, let the water go to avoid any oxidation, and easy for your next use.

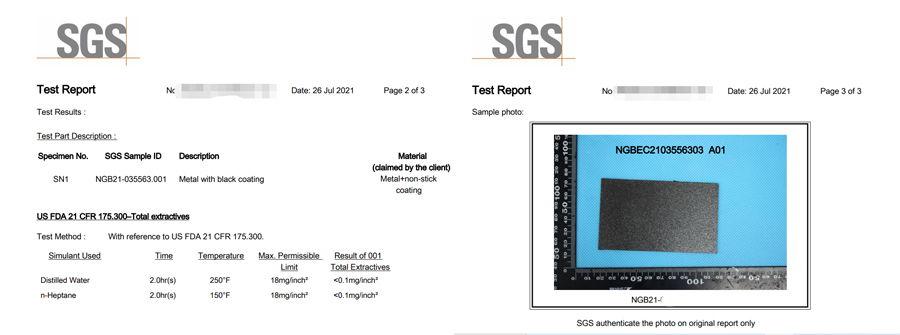

Chapter 11. What are the certificates of your candy molds?

The molds must be food standard, and we have SGS and CE certificates. Help you to get your factory FDA certificates.

Chapter 12. Why iSweetech?

- iSweetech is a Professional Manufacturer of different kinds of candy molds, like hard candy molds, lollipop molds, gummy candy molds, etc.

- iSweetech has skilled mold designers to let your idea come to real candy.

- The candy molds are food standards and have SGS certificates.